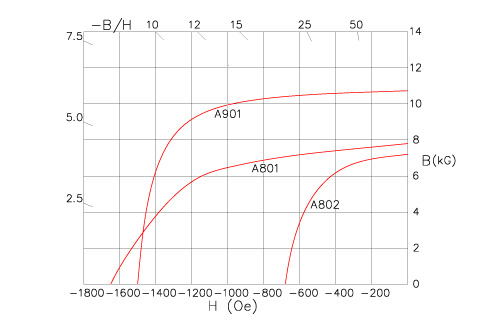

A801

Material Properties

Norm.

Min.

Br (Gauss)

8,200

7,500

Hc (Oersted)

1,650

1,550

Hk (Oersted)

N/A

N/A

Hci (Oersted)

1,850

1,700

BHmax (MGOe)

5.3

5

Temp Coeff of Br (%/°C)

-0.01

N/A

Recoil Permeability (µrec)

N/A

N/A

Tc, Curie Temperature (°C)

860

N/A

Maximum Operating Temperature (°C)

550

N/A

Physical Properties

Density (Ibs/in3)

0.26

Coeff of Linear Expan. ⊥ to < M > (10-7/°C approx)

114

Coeff of Linear Expan. // to < M > (10-7/°C approx)

114

Compressive Strength (psi x 103)

N/A

Young’s Modulus (psi x 106)

N/A

Vicker’s Hardness (HV)

N/A

Tensile Strength (psi x 106)

Flexural Strength (psi x 106)

N/A

Common Industry Name

Alnico 8

Electrical Resistivity (μΩ.cm)

N/A

Typical Appearance

Metallic